Blow off valves, vital for high-performance vehicles, ensure safe pressure release and optimize airflow. Correct installation is critical to prevent performance issues and engine damage. Common mistakes include misalignment leading to leaks and reduced power, requiring precise alignment with seamless hardware integration. Proper installation enhances engine health, combustion efficiency, and exhaust functionality.

“Avoid common pitfalls in blow off valve installation with our comprehensive guide. Understanding these essential components, their basics, and benefits is crucial for optimal engine performance. Learn about common errors, such as incorrect positioning or improper sealing, that can lead to power loss and increased wear. This article equips you to correct mistakes, ensuring your vehicle’s engine runs smoothly and efficiently, maximizing the advantages of blow off valves.”

- Understanding Blow Off Valves: Basics and Benefits

- Common Installation Errors to Watch Out For

- Correcting Mistakes for Optimal Performance

Understanding Blow Off Valves: Basics and Benefits

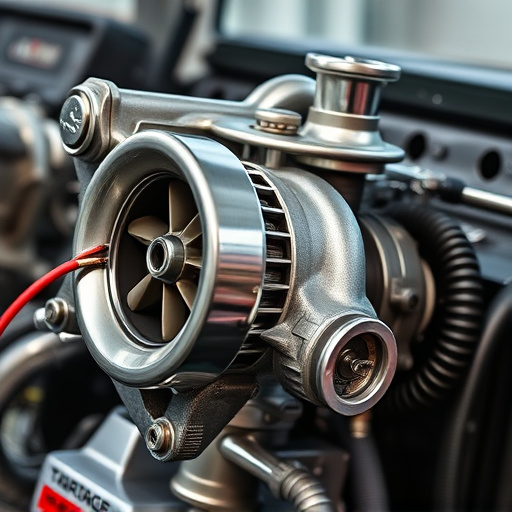

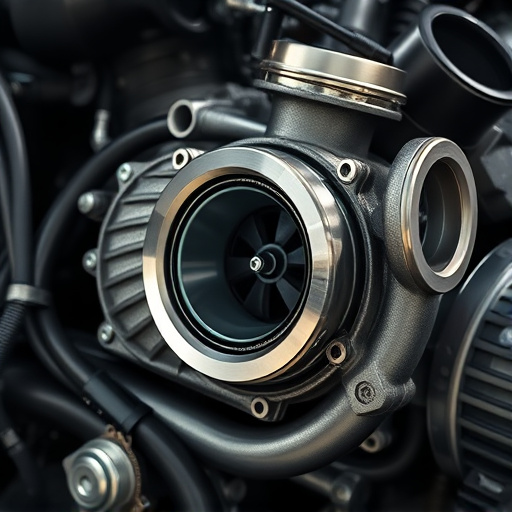

Blow off valves, an integral part of any high-performance vehicle’s engine management system, serve a crucial purpose in enhancing engine performance and reliability. These valves are designed to release pressure from the intake components, allowing for smoother air flow and preventing damage to sensitive exhaust mufflers. By venting compressed air, blow off valves ensure that only optimal amounts of atmospheric pressure are fed into the engine, leading to improved power output and fuel efficiency.

Understanding their functionality is essential when it comes to installation. Proper placement and secure fitting are key; incorrect installation can result in inefficient venting or even engine damage. With high-performance parts becoming increasingly popular among car enthusiasts, ensuring the correct use of blow off valves is vital for maintaining the overall health of the vehicle’s engine, especially under intense conditions.

Common Installation Errors to Watch Out For

When installing blow off valves, several common mistakes can compromise both vehicle performance and safety. One of the most frequent errors is improper alignment, which can lead to leaks or inadequate airflow. It’s crucial to ensure the valve is correctly positioned according to the manufacturer’s guidelines. Incorrect mounting can also cause issues with the vehicle’s brake rotors, affecting braking efficiency.

Another mistake to avoid is overlooking the compatibility of the blow off valve with your cold air intake system. Incompatibility may result in reduced engine power and even damage to sensitive components. Always check that all hardware is included and that the valve seamlessly integrates with your vehicle’s existing setup, enhancing overall performance rather than creating new problems.

Correcting Mistakes for Optimal Performance

Correcting installation mistakes with blow off valves is essential for achieving optimal vehicle performance and ensuring your car’s engine remains in top shape. These valves play a crucial role in managing air flow, allowing for efficient combustion and enhancing overall exhaust system functionality. If installed incorrectly, it can lead to various issues such as reduced power output, irregular idling, and even potential damage to the engine.

When addressing installation errors, focusing on details is key. Ensure proper alignment of the blow off valve with the corresponding components in your vehicle’s intake system. This includes accurate positioning relative to the turbocharger or supercharger, if equipped. Additionally, checking the integrity of connections and seals is vital to prevent leaks that could negatively impact both engine performance and fuel efficiency. Using high-quality replacement parts, especially when integrating with coilover kits or modifying exhaust systems, can significantly contribute to long-term reliability and superior vehicle performance.

When installing blow off valves, whether for performance or safety purposes, it’s crucial to avoid common mistakes that can lead to suboptimal results. By understanding the basics and benefits of these valves and taking precautions against installation errors, you ensure smooth operation and maximize their advantages. Regular maintenance and correct setup are key to reaping the full potential of blow off valves in your system.