Blow off valves, critical components in high-performance automotive engines, regulate released compressed air, preventing pressure buildup & damage to turbochargers/superchargers. Improper installation or damage leads to inefficient air venting, engine stuttering, power loss, and potential harm to other parts. Regular maintenance & timely replacement are vital for optimal vehicle performance. Leaks, debris, or damage should be addressed during troubleshooting, synchronizing with the engine cycle for effective repair & ensuring compatibility of replacement parts with upgraded systems.

“Unleash peak engine performance with a seamless understanding and troubleshooting of blow off valves. This comprehensive guide deciphers the intricate functions of these vital components, illuminating common errors that can hinder your vehicle’s power and efficiency. From misfires to unusual noises, we demystify potential issues, offering practical troubleshooting tips for effective repairs. Master the art of maintaining optimal engine health with our expert insights into blow off valves.”

- Understanding Blow Off Valves and Their Function

- Identifying Common Blow Off Valve Errors

- Troubleshooting Tips for Effective Repair

Understanding Blow Off Valves and Their Function

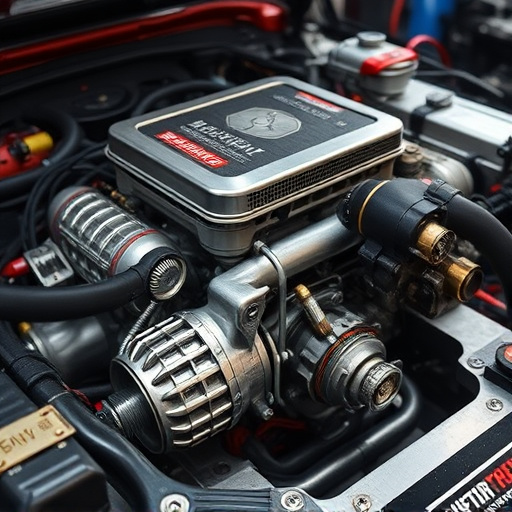

Blow off valves are integral components in automotive systems, particularly in high-performance vehicles equipped with turbocharged or supercharged engines. Their primary function is to regulate and release compressed air from the engine’s intake system during certain operating conditions. This process prevents excess pressure buildup within the air intake systems and performance exhaust, ensuring optimal engine performance and efficiency.

These valves play a crucial role in maintaining the balance between engine compression and airflow. When the engine’s boost pressure exceeds a set threshold, the blow off valve opens to divert the surplus air, preventing potential damage to the turbocharger or supercharger. Additionally, they facilitate smoother transitions during engine operation, especially during rapid acceleration or deceleration, by allowing for controlled ventilation of compressed air from the intake system and performance air filters.

Identifying Common Blow Off Valve Errors

Blow off valves are an essential component of many automotive systems, particularly those with turbocharged or supercharged engines. When these valves fail to function properly, it can lead to a range of issues that affect engine performance and overall driving experience. Identifying common errors early on is crucial for maintaining optimal vehicle health.

One frequent problem with blow off valves is incorrect installation or misalignment during the initial setup. This can result in inefficient venting of compressed air from the intake system, causing unexpected behavior in the engine, such as stuttering or loss of power. Another issue arises when the valve becomes contaminated with debris from the exhaust mufflers or damaged by rough road conditions, leading to a partial or complete blockage. This, in turn, can damage other components like coilover kits and air intake systems, emphasizing the need for regular maintenance and prompt replacement if necessary.

Troubleshooting Tips for Effective Repair

When troubleshooting blow off valves, start by checking for any leaks around the valve and its connections. Even a small leak can cause significant issues, so ensure all gaskets and seals are in pristine condition and properly seated. If leaks persist, inspect the valve itself; debris or damage could be obstructing its operation. A simple cleaning or replacement might resolve the problem.

Remember that proper timing is crucial when addressing blow off valves. Synchronize your actions with the engine’s cycle for effective repair. Additionally, consider the compatibility of any replacement parts, especially if upgrading or installing new systems like a cat back exhaust or suspension kits. Ensuring these components work harmoniously will prevent future problems and guarantee optimal performance.

Blow off valves are essential components in various mechanical systems, ensuring efficient gas release. By troubleshooting common errors, you can prevent costly damage and maintain optimal performance. With these tips, you’re equipped to identify issues, make informed decisions, and effectively repair your blow off valves, keeping your machinery running smoothly. Remember, prompt action on potential problems is key to avoiding larger, more complex repairs in the future.