Blow off valves (BOVs) are essential for optimizing engine performance in customized vehicles. They regulate exhaust pressure, enhancing power output and efficiency. When customizing BOVs, consider engine specifics like displacement, compression ratio, and power output. Integration with air filters, intakes, and exhaust systems is vital for optimal performance. Proper installation, adjustment, and testing are key to achieving balanced power delivery and handling improvements.

Unleash your engine’s full potential by customizing your blow off valves (BOVs). BOVs play a crucial role in turbocharging systems, regulating pressure release and enhancing performance. This article guides you through the process of fine-tuning these components for unique engine setups. We’ll explore key factors to consider, from turbine outlet pressure to sound preferences. Learn how to choose the right valve size, material, and even design for a personalized, high-performance experience.

- Understanding Blow Off Valves: Their Role and Functionality

- Factors to Consider When Customizing Blow Off Valves

- Step-by-Step Guide: Customizing Your Blow Off Valve for Optimal Performance

Understanding Blow Off Valves: Their Role and Functionality

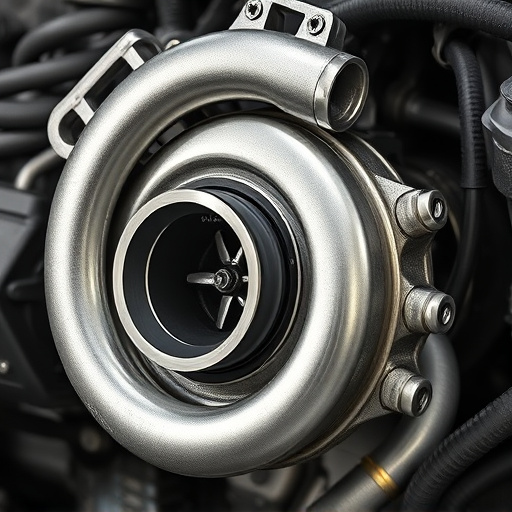

Blow off valves (BOVs) are an essential component in automotive engineering, designed to regulate pressure within an engine’s exhaust system. Their primary role is to quickly and efficiently release excess pressure built up during combustion, ensuring optimal engine performance. By allowing for a controlled venting of gases, BOVs prevent backpressure from building up inside the cylinders, which can hinder engine efficiency and power output. This functionality is crucial, especially in high-performance engines where precise control over intake and exhaust gas flow can significantly enhance overall engine setup.

In customized vehicle setups, such as those featuring modified intake and exhaust systems or coilover kits, understanding the dynamics of blow off valves becomes even more critical. For example, when paired with larger brake rotors and upgraded brake pads to handle increased stopping power, the engine may require enhanced ventilation to maintain stability during aggressive driving conditions. BOVs can be tailored to facilitate this by allowing for a strategic release of pressure, enhancing drivability and ensuring that other components, like exhaust systems, operate within their designed parameters.

Factors to Consider When Customizing Blow Off Valves

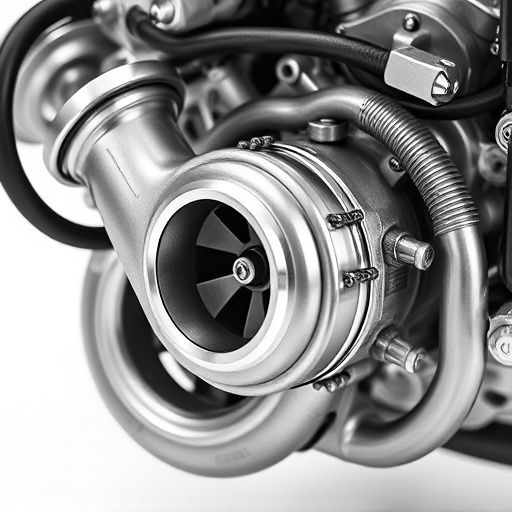

When customizing blow off valves for unique engine setups, several factors come into play. Firstly, the type and design of the engine itself is crucial, as different engines have varying requirements in terms of air flow and pressure regulation. Understanding the engine’s specifications, including its displacement, compression ratio, and power output, is essential to select or design a blow off valve that can effectively manage the engine’s breathing dynamics.

Additionally, integrating performance air filters and cold air intakes into the setup requires careful consideration. These components can significantly impact airflow, which in turn affects the operation of the blow off valve. The compatibility between these parts and the valve must be ensured to maintain optimal performance. Moreover, exhaust systems also play a role, as they influence overall engine efficiency and emissions. Customizing the blow off valve should complement the upgrades or modifications made to the exhaust system for harmonious engine tuning.

Step-by-Step Guide: Customizing Your Blow Off Valve for Optimal Performance

Customizing your blow off valve (BOV) is a powerful way to enhance engine performance and fine-tune your vehicle for optimal dynamics. Here’s a step-by-step guide to help you achieve just that:

1. Assess Your Engine Setup: Begin by understanding your unique engine configuration, including the type of engine, compression ratio, and existing exhaust system (including headers and exhaust tips). This knowledge will guide your BOV selection and customization choices.

2. Choose the Right Blow Off Valve: Select a BOV designed for high-performance applications that can handle the horsepower and torque output of your modified engine. Consider factors like boost pressure, airflow requirements, and sound level preferences. High-performance parts manufacturers offer a range of BOVs catering to various driving styles and engine setups.

3. Install According to Manufacturer Instructions: Ensure proper installation by following the guidelines provided by the BOV manufacturer. This typically involves connecting the valve between the turbocharger outlet and the intake manifold, along with attaching the vent line to direct exhaust gases away from the engine.

4. Adjust for Optimal Performance: After installation, tweak the settings for best results. This might involve playing with the boost threshold, wastegate pressure, or spring tension (if adjustable). The goal is to balance power delivery and maintain a smooth ride while unlocking your engine’s full potential.

5. Test and Iterate: Take your vehicle for test drives under various conditions—from cruising on highways to aggressive driving around tracks. Monitor performance indicators like horsepower gains, response times, and turbo lag (if any). Adjust the BOV settings accordingly until you achieve the desired balance between power and control.

6. Integrate with Other Upgrades: Remember that your BOV works in harmony with other high-performance parts like suspension kits. Ensure these modifications are compatible to maximize overall vehicle dynamics and handling, creating a cohesive setup for optimal performance.

Customizing blow off valves (BOVs) is an art that can significantly enhance your engine’s performance, especially in unique setups. By understanding the fundamentals of BOVs and tailoring them to your specific requirements, you unlock a world of improved throttle response, reduced backpressure, and a more exhilarating driving experience. With the right adjustments, these simple yet powerful components can transform your vehicle into a true force on the road, ensuring an optimal balance between engine health and breathtaking performance.