Blow off valves (BOVs) are essential for turbocharged/supercharged cars, releasing compressed air to prevent engine damage from pressure buildup. Common BOV issues like unusual noises, power loss, or overheating should be addressed through inspections and maintenance. Regular checks, visual inspections, and functional tests ensure optimal vehicle performance by maintaining engine health and efficient ride quality in high-performance vehicles.

In the realm of automotive performance, blow off valves (BOVs) play a crucial role in engine health and efficiency. This article serves as a comprehensive guide for car enthusiasts and mechanics alike, delving into the intricacies of BOVs, their basic operation, and most common errors. By understanding these symptoms, you’ll master troubleshooting and fixing BOVs with ease, ensuring optimal engine performance and longevity. Let’s dive into the world of blow off valves.

- Understanding Blow Off Valves: Their Role and Basic Operation

- Identifying Common Blow Off Valve Errors and Symptoms

- Troubleshooting and Fixing Blow Off Valves: A Step-by-Step Guide

Understanding Blow Off Valves: Their Role and Basic Operation

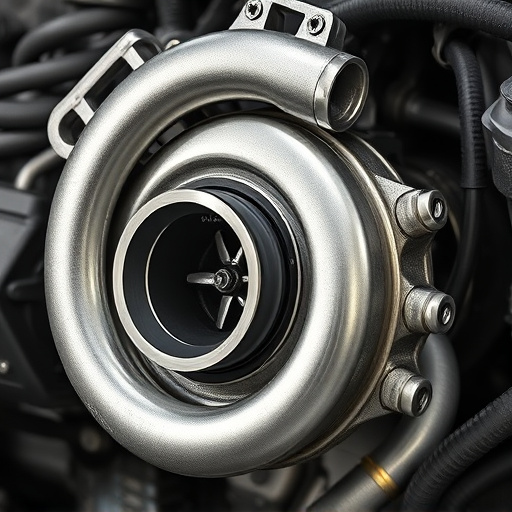

Blow off valves are an integral component of many vehicles’ cooling systems, particularly those with turbocharged or supercharged engines. Their primary role is to quickly release compressed air from the engine’s combustion chamber when necessary, preventing excessive pressure buildup that could potentially cause damage. By venting this high-pressure air, blow off valves maintain optimal engine performance and prevent boost loss in turbocharged vehicles.

These valves operate through a simple yet efficient mechanism. When the engine reaches a certain speed or pressures, the blow off valve opens, allowing compressed air to escape into the atmosphere. This process is typically controlled by a vacuum or electronic signal from the vehicle’s management system, ensuring precise timing and regulation. In many high-performance vehicles, these valves are integrated with suspension kits or coilover kits, which enhance vehicle performance by improving ride quality and handling dynamics while also contributing to overall engine efficiency and stability.

Identifying Common Blow Off Valve Errors and Symptoms

When it comes to identifying common blow off valve errors, several symptoms can serve as red flags. One of the most noticeable signs is an unusual noise coming from your vehicle’s engine bay during acceleration or deceleration. This could indicate a loose connection, damaged components, or a malfunction in the valve itself. Another symptom to look out for is a sudden loss of power or performance, especially when transitioning from high to low RPMs. This might be caused by clogged vents or an incorrect setup, leading to inadequate air flow and affecting overall engine performance.

Moreover, unexpected vibrations or jerks while driving can point towards issues with the blow off valve system. These problems often stem from improper adjustments or worn-out parts, such as faulty actuators or damaged springs. Additionally, monitoring your vehicle’s temperature gauge is crucial; persistent overheating could suggest a blocked vent or inefficient cooling due to incorrect valve operation, affecting both engine health and overall performance brakes. Don’t forget to check for leaks around the blow off valve area, especially when using high-quality performance air filters, as they can provide better airflow but also increase the risk of minor leaks if not properly sealed.

Troubleshooting and Fixing Blow Off Valves: A Step-by-Step Guide

Troubleshooting blow off valves requires a systematic approach to identify and rectify issues effectively. Begin by visually inspecting the valve for any signs of damage or debris buildup, which could hinder its operation. Check for proper installation, ensuring all connections are secure and aligned correctly. Leaks often occur due to worn-out O-rings or damaged seals; replacing these components is crucial for seamless performance.

Next, verify that the venting system is unobstructed, as clogged vents can cause valve malfunction. Test the valve’s functionality by ensuring it fully opens and closes during engine operation, especially under varying load conditions. If the valve fails to respond, consider adjusting the spring pressure or checking sensor signals, which play a vital role in controlling the valve’s activation. Regular maintenance, including cleaning and lubrication, is essential to prevent future problems with suspension components, cat-back exhaust systems, and performance brakes, ensuring optimal vehicle performance.

Understanding and maintaining your car’s blow off valves is crucial for optimal engine performance. By identifying common errors early on, you can prevent more serious issues down the line. The troubleshooting guide provided offers practical solutions to fix these problems efficiently. Equip yourself with this knowledge, and keep your vehicle running smoothly by regularly checking and servicing your blow off valves.