Blow off valves, vital in high-performance cars, manage engine pressure, preventing damage from turbochargers/superchargers. Common issues include debris buildup and corrosion, requiring regular cleaning and inspection for optimal performance and extended valve lifespan. Proper maintenance is key to avoiding costly repairs associated with inefficient or faulty blow off valves.

In any car enthusiast’s arsenal, understanding and maintaining blow off valves is crucial. These mechanical marvels regulate exhaust gas flow in turbocharged engines, enhancing performance while protecting components. However, common problems like unexpected detonation, strange noises, and loss of power can arise. This article delves into the world of blow off valves, exploring their common issues, diagnosing causes, and offering effective fixes along with essential maintenance tips for optimal engine health.

- Understanding Blow Off Valves and Their Common Issues

- Diagnosing Problems and Their Causes

- Effective Fixes and Maintenance Tips

Understanding Blow Off Valves and Their Common Issues

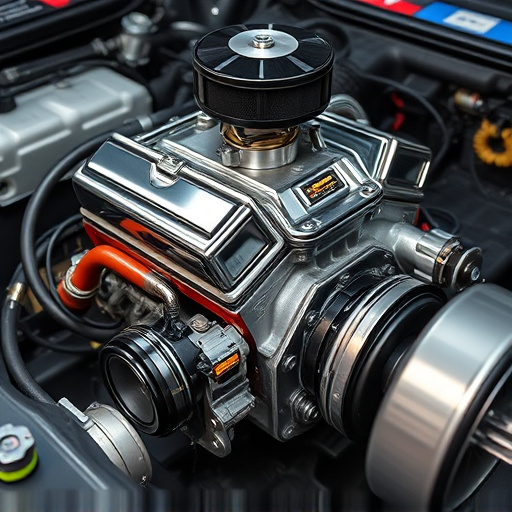

Blow off valves, often overlooked components in automotive systems, play a vital role in managing pressure within engines, particularly during high-performance conditions. These valves are designed to release excess pressure from the combustion chamber when turbochargers or superchargers boost engine power, preventing potential damage to critical parts like pistons and heads. By allowing quick expulsion of compressed gases, they contribute to maintaining optimal engine performance and efficiency.

Common issues with blow off valves can stem from various factors. Debris buildup or clogging due to contaminated air intake is a frequent problem, leading to restricted airflow and potential engine performance issues. Corrosion, especially in salty environments, can also impact the valve’s functionality. Additionally, improper installation or compatibility with high-performance parts, such as suspension kits or upgraded exhaust tips, might cause premature failures. Regular maintenance, including cleaning and inspection, is crucial to address these concerns, ensuring smooth operation and extending the lifespan of both the blow off valve and the engine it protects.

Diagnosing Problems and Their Causes

Many car enthusiasts often overlook the importance of regular blow off valve maintenance, which can lead to a variety of problems within their vehicle’s engine and exhaust systems. Diagnosing these issues early is crucial in preventing more serious complications, especially when it comes to the intricate workings of air intake systems. Blow off valves play a vital role in regulating pressure, ensuring that excess gases are safely vented from the turbocharger or supercharger. When these valves malfunction, it can cause a cascade of unwanted effects, such as reduced engine performance and increased wear on components like muffler tips and cat back exhaust systems.

Common causes of blow off valve problems include debris buildup, worn-out seals, or incorrect adjustments. Debris like carbon deposits can obstruct the valve’s internal mechanism, leading to improper operation. Worn seals may result in leaks, affecting pressure regulation. Moreover, incorrect adjustments during installation or maintenance can cause the valve to stick or malfunction. Regular cleaning and inspection are essential to address these issues, ensuring optimal performance of both the blow off valve and the overall engine breathing system.

Effective Fixes and Maintenance Tips

Effective Fixes and Maintenance Tips for Blow Off Valves

Regular maintenance is key to preventing common blow off valve issues. One simple yet effective tip is to ensure periodic cleaning, especially if your vehicle sees heavy use or frequent extreme temperature changes. Dust, debris, and carbon buildup can hinder proper valve operation, negatively impacting both vehicle performance and engine longevity. Using compressed air to blast away any blockages and applying a lightweight lubricant designed for automotive components can help maintain smooth airflow through the air intake systems.

Additionally, checking the state of your brake rotors and replacing them if necessary is crucial. Worn or warped rotors can cause uneven pressure on the blow off valve, leading to malfunctions. Regular inspection of all components in the exhaust and air intake systems will help identify any signs of damage or wear early on, making it easier and more cost-effective to implement fixes before they become major issues.

Blow off valves are essential components in many automotive systems, but like any part, they can develop issues over time. By understanding common problems like backpressure buildup, leaks, and performance degradation, car owners can effectively diagnose and address these challenges using simple fixes or regular maintenance tips. Regular checks and timely repairs ensure optimal engine health and performance, maximizing the lifespan of your vehicle’s blow off valves.